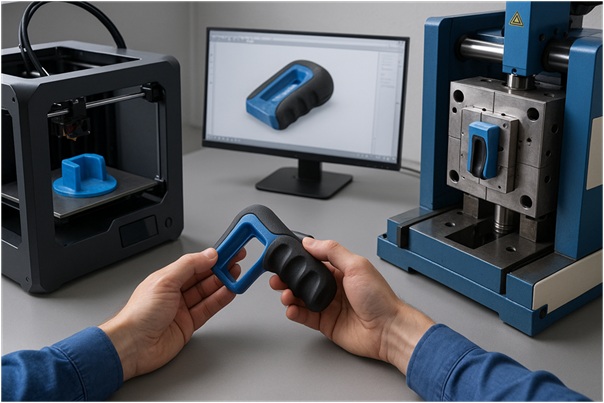

In today’s race to bring products to market faster and smarter, manufacturers are blending traditional methods with cutting-edge technologies. One of the most promising combinations is the integration of 3D printing and plastic injection overmolding. This hybrid approach is redefining how prototypes, short-run production parts, and even functional components are designed and manufactured.

By leveraging the strengths of both technologies—speed and flexibility from 3D printing, and durability and precision from overmolding—OEMs and startups alike are discovering a faster, more cost-effective path from concept to production.

Why Combine 3D Printing and Overmolding?

3D printing excels in low-volume production and design iteration. Engineers can create highly detailed parts in a matter of hours, test fit and form, and refine geometries quickly. However, 3D-printed parts often fall short when it comes to durability, surface finish, and long-term performance—especially in demanding applications.

That’s where overmolding comes in. By using a 3D-printed component as the base, manufacturers can overmold a second material—such as a flexible TPE, rigid ABS, or even transparent polycarbonate—to enhance structural strength, aesthetics, grip, or protection. This allows for functional, production-grade parts to be created without waiting weeks for steel tooling.

Key Benefits of the Hybrid Process

1. Rapid Prototyping with Functional Parts

Instead of producing basic visual models, engineers can now prototype components that perform like final products. For example, a 3D-printed electrical housing can be overmolded with a soft-touch material to simulate grip and impact resistance. These hybrid prototypes can be used for real-world testing before investing in final molds.

2. Faster Iterations

Because 3D prints can be modified instantly based on test feedback, this process allows multiple design cycles in days rather than weeks. It eliminates the bottleneck of retooling during the early phases of development.

3. Cost-Effective Bridge Production

For projects that require limited quantities before full-scale production, hybrid overmolding offers a cost-effective solution. This is especially valuable for pilot runs, clinical trials, or investor presentations—where parts must look and function like production units.

4. Design Freedom

3D printing allows for complex geometries and internal structures that would be difficult or impossible to machine. These features can be retained in the overmolded part, opening new possibilities in part performance and integration.

Real-World Applications

- Medical Devices: Custom-fit components like ergonomic grips, surgical tool housings, or personalized wearables.

- Consumer Products: Limited-run promotional items, smart devices with soft grips, or waterproof enclosures.

- Automotive: Prototypes for switches, knobs, and dashboard components with tactile finishes.

Even in high-performance industries, this hybrid technique is gaining traction—especially when timelines are tight and flexibility is critical.

Things to Consider

While the process is efficient, it requires close attention to material compatibility. Not all 3D-printed resins or filaments bond well with overmolding materials. Engineers must select base materials that can withstand the heat and pressure of injection without warping or delaminating.

Partnering with a supplier experienced in both additive manufacturing and custom mold manufacturing is key. These providers can guide you in choosing compatible materials, adjusting tolerances, and preparing 3D-printed parts for successful overmolding.

The Future of Agile Manufacturing

As production cycles continue to shrink and customization becomes the norm, hybrid processes like 3D printing with overmolding will only become more important. They offer an agile solution that meets the demands of both design and performance—without the traditional delays of tooling and production setup.

For OEMs looking to compress timelines without compromising quality, this strategy is a powerful option. It brings together the innovation of 3D printing with the trusted results of plastic injection overmolding, creating a smarter path from concept to consumer—while reducing costs, enabling faster iterations, and supporting limited-run or pilot-scale production with real-world functionality.

Refresh Date: August 21, 2025